Reimagining Manufacturing with Intelligent Data and AI

Delivering agility and precision across supply chains, plants, and finance with cloud-native data and AI platforms.

- Home

- »

- Manufacturing and Distribution

From Smarter Machines to Smarter Margins — The Future is Data-Led

As manufacturers embrace Industry 4.0, intelligent data and AI platforms have become critical to stay competitive. We help you reimagine production, procurement, and performance with scalable, cloud-first technologies that turn complexity into control.

- Integrate data from machines, ERP, and finance to break silos

- Modernize legacy platforms without disrupting mission-critical processes

- Gain financial clarity with real-time reporting and dynamic budgeting

- Automate financial planning, demand forecasting, and inventory optimization

- Make every process—from procurement to payroll—smarter and faster

Smarter Factories, Sharper Insights, Stronger Margins

ROI on data platform modernization initiatives

Increase in supply chain visibility and responsiveness

Acceleration in financial consolidation and planning cycles

Faster decision-making with unified reporting and dashboards

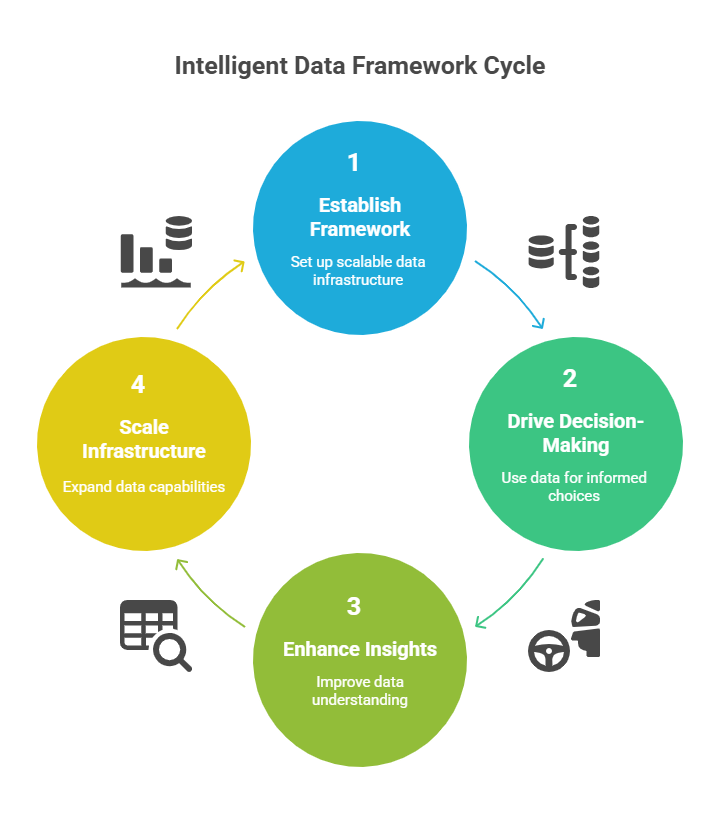

Turning Data into Direction—Smarter Decisions at Every Level

From extended planning and consolidations to payroll modeling and profitability analysis, we deliver a holistic performance management suite. Built for CFOs, business users, and FP&A teams looking to simplify complexity and maximize value

Intelligent Data Foundations

Cloud-native data platforms for manufacturing data consolidation from ERPs, IOT and MES systems

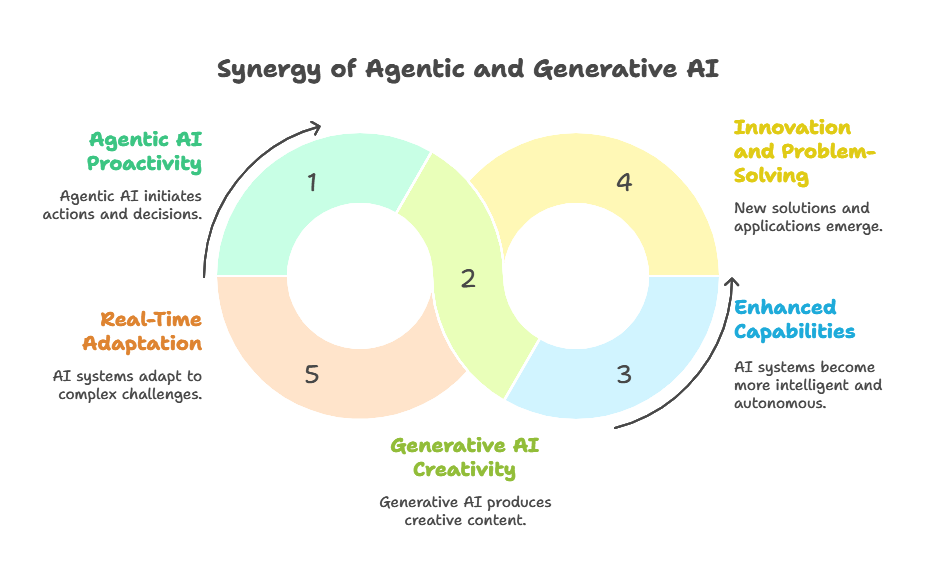

Agentic AI for Workflow Orchestration

Deploy intelligent AI agents that autonomously coordinate tasks across inventory, production planning, quality checks, and supply chain processes — reducing manual intervention.

Financial Planning for Manufacturing Ops

Expert guidance and strategic advice on integrating neural networks into your existing systems

Operational Analytics & Performance Monitoring

Track KPIs across throughput, yield, and downtime with visual dashboards that help operators and executives drive efficiency.

Workforce and Labor Cost Optimization

Plan, budget, and analyze workforce costs and capacity using integrated planning models and AI-driven insights.

Demand Forecasting & Inventory Optimization

Anticipate market shifts and streamline inventory with ML-powered forecasting, minimizing stockouts and excess while maximizing service levels.

GenAI copilots for Manufacturing

Automate technical documentation, SOPs, compliance reports, and knowledge bases using Large Language Models (LLMs) trained on internal manufacturing data.

Insights That Inspire Change

How AI is being used to provide personalized shopping experiences and improve customer satisfaction

How AI is being used to provide personalized shopping experiences and improve customer satisfaction

Client Success Stories

Explore how our end-to-end solutions, from strategy to implementation, have delivered measurable results. Through expert partnerships and cutting-edge technologies, we empower clients to overcome challenges, drive growth, and unlock new value across industries.

Modernized self Service BI platform

Leveraging capabilities of Microsoft data platform implemented EDW, data marts, suite of Power BI reports along with forecasting and budgeting capabilities for a Home Health and hospice company

Configurable data solution with ready to use BI

Our solution offers the flexibility to seamlessly integrate plug-and-play analytics with a wide range of data sources, including QuickBooks, GP, Salesforce, Sage, Business Central, and more.

Data Hub for near real time analytics

Constructed a robust data hub featuring multiple tiers (Bronze, Silver, and Gold), enabling near real-time analytics by seamlessly collecting data from over 10 diverse sources.

Streamlining fund statements generation

Engineered an enterprise data warehouse for accurate fund statements, replacing operational data stores. This streamlines fund statement generation and redesigns distribution processes for optimal efficiency.

Financial reporting and budgeting for a group of 18 companies

Built an enterprise data warehouse that seamlessly ingests data from diverse entities. Our solution empowers self-service BI modeling, facilitating the creation of accurate financial statements and dynamic budgeting templates.

Got Questions? We have answers.

How can AI and Machine Learning improve operational efficiency in manufacturing?

AI and ML can optimize everything from predictive maintenance and demand forecasting to quality control and supply chain operations. By automating repetitive tasks and generating real-time insights, manufacturers reduce downtime, enhance throughput, and make data-driven decisions faster.

We have legacy ERP and MES systems. Can your solutions integrate with our existing infrastructure?

Absolutely. Our data engineering services are designed with interoperability in mind. We offer robust integration with 40+ on-prem and cloud-based ERP, MES, CRM, and SCM platforms to unify your data without needing a complete system overhaul.

What kind of business impact can we expect from AI-powered demand forecasting?

Our clients have seen up to 30% reduction in inventory holding costs and 15% improvement in on-time delivery through AI-enhanced forecasting models. These models adapt to changing market variables, seasonality, and external disruptions in real time.

How do you ensure data governance and compliance across global operations?

We embed compliance and governance frameworks into our data architectures, supporting multi-entity, multi-currency operations. From GDPR to industry-specific standards, we help you maintain traceability, data lineage, and secure access across your global manufacturing footprint.

What does corporate performance management look like for a manufacturing enterprise?

Our CPM solutions go beyond budgeting and reporting. We offer margin analysis, SKU-level profitability, CapEx planning, and real-time workforce cost modeling—all tailored for manufacturing and distribution environments.

How quickly can we deploy analytics dashboards or AI models for production use?

With our pre-built templates, accelerators, and modular AI models, most of our clients go live with custom dashboards and predictive tools in 6–10 weeks, depending on data availability and complexity.

Can your solutions support smart factory or Industry 4.0 initiatives?

Yes. Our intelligent data platforms and AI capabilities support smart factory transformation by enabling real-time machine data analysis, digital twins, sensor integration, and autonomous decision-making frameworks.

What’s your approach to change management and user adoption in traditional manufacturing environments?

We combine intuitive dashboards, self-service analytics, and continuous training to ensure teams—from shop floor to leadership—adopt and benefit from the solutions. Our focus is on value realization, not just deployment.

Power Your Plant with Data. Fuel Growth with AI.

Book a consultation and see how we blend AI, analytics, and performance strategies to drive measurable impact.